The RMIT University engineers collaborated with Visy – Australia’s largest recycling company – to make bricks with a minimum of 15% waste glass and 20% combusted solid waste (ash), as substitutes for clay.

RMIT says test results indicate that using these bricks in the construction of a single-storey building could reduce household energy bills by up to 5% compared to regular bricks, due to improved insulation - and replacing clay with waste materials in the brick production helped reduce the firing temperature by up to 20% compared with standard brick mixtures, offering potential cost savings to manufacturers.

Team leader Associate Professor Dilan Robert said about 1.4 trillion bricks were used in construction projects globally every year.

|

|

“Business-as-usual brick production produces harmful emissions – including carbon dioxide, sulphur dioxide and chlorine – and puts a serious strain on our natural resources, particularly clay,” said Dilan, from RMIT’s School of Engineering.

The team’s latest research is published in the international journal Construction and Building Materials, with the research showing the new bricks have enhanced energy efficiency through improved thermal performance, and met stringent structural, durability and environmental sustainability standards.

RMIT says the technology has met the key compliance requirement of fired clay bricks set by Standards Australia (AS 3700).

“Bricks play a key role in preventing energy loss from buildings,” Robert said.

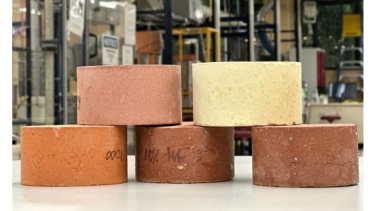

“We can also produce light-weight bricks in a range of colours from white to dark red by changing our formulations.”

Dr Biplob Pramanik, the RMIT team’s environmental engineer, said the new bricks were safe to use in construction projects.

“Our bricks, manufactured from industry waste, meet state environmental regulations,” he said.

In Victoria, Visy recycles glass packaging back into new bottles and jars. However, glass pieces smaller than 3mm – referred to as fines – cannot be recycled into bottles.

“We are focusing on scaling up the production process to facilitate the commercialisation of our innovative bricks in collaboration with brick manufacturers in Melbourne,” Robert said.

Paul Andrich, Innovation Project Manager at Visy, said the company was thrilled to find a solution for material that cannot be recycled into food and beverage packaging.

“Diverting this waste into bricks with added insulation, rather than landfill, is another way we are powering the circular economy," he said.

RMIT says the research team wants to collaborate with industries to explore applications of waste material in other construction products.